Table of Contents

ToggleIn a world where everything seems to be shrinking—phones, attention spans, and even our patience—large-scale 3D printing is the refreshing giant we didn’t know we needed. Imagine a technology that can whip up anything from a life-sized replica of a dinosaur to entire houses, all while sipping on a cup of coffee. It’s like having a magic wand, but instead of spells, it’s all about precision and innovation.

Overview of Large-Scale 3D Printing

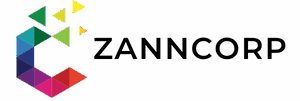

Large-scale 3D printing serves as a breakthrough in manufacturing, enabling the production of enormous and complex structures. Utilizing various materials, such as polymers, metal, and concrete, this technology adapts to numerous applications, ranging from architecture to aerospace. Creating components that traditional methods struggle with is one of its primary advantages, allowing for intricate designs and innovative solutions.

Key companies in the sector leverage advanced techniques like robotic arms and gantry systems to execute large builds. These methods enhance precision and efficiency, often reducing production times significantly. Recent projects demonstrate large-scale 3D printing potential, including entire building structures completed in a matter of days.

In industries such as construction, large-scale 3D printing lowers costs and minimizes waste. For instance, researchers report that up to 30% less material is used compared to conventional construction practices. Additionally, the technology supports sustainable development by promoting eco-friendly materials and reducing energy consumption.

Fostering collaboration between engineers and designers, large-scale 3D printing encourages innovation while also addressing practical challenges. Teams can iterate designs quickly, making adjustments that optimize performance and functionality. This iterative process leads to new possibilities, resulting in a shift toward agile manufacturing strategies.

Applications span across diverse fields, showcasing adaptability and transformative potential. From producing intricate art installations to manufacturing large aerospace components, large-scale 3D printing reshapes traditional paradigms. Its influence continues to expand, promising a future where efficiency and creativity coexist seamlessly.

Applications of Large-Scale 3D Printing

Large-scale 3D printing finds application across various industries, revolutionizing traditional practices and encouraging innovation. Its versatility enables the creation of large and intricate structures with precision and efficiency.

Construction Industry

In the construction industry, large-scale 3D printing transforms building methods by enabling the rapid production of homes and infrastructure. Companies report a reduction in construction time by up to 70%, allowing for quicker project completions. Material efficiency stands out, with studies showing a 30% decrease in waste compared to conventional construction approaches. This technology utilizes concrete and sustainable materials, promoting eco-friendly practices. Innovations include the ability to create complex designs that traditional methods often struggle with. By supporting modular construction techniques, large-scale 3D printing enhances flexibility in both design and assembly.

Aerospace and Automotive

The aerospace and automotive sectors leverage large-scale 3D printing for producing lightweight and complex parts. Manufacturers can create components with optimized geometries, leading to improved fuel efficiency and performance. Aerospace companies benefit from using advanced materials like titanium and carbon fiber, which offer durability while reducing weight. Notable reductions in lead times enhance adaptability in production processes. Automotive applications include the rapid prototyping of parts for testing new designs and concepts. Innovations within these industries empower engineers and designers to explore intricate designs that drive performance and safety.

Technologies Used in Large-Scale 3D Printing

Large-scale 3D printing employs various technologies, revolutionizing manufacturing processes across multiple industries.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling remains a widely adopted method in large-scale 3D printing. It uses a thermoplastic filament, heated and extruded layer by layer to create objects. This technology excels in producing intricate designs with a relatively low cost and high speed. Industries leverage FDM for creating prototypes and functional parts due to its accessibility and reliability. Manufacturers appreciate the variety of materials available for FDM, including PLA and ABS, which enhance versatility. Applications often include producing components for automotive, aerospace, and consumer products.

Powder Bed Fusion

Powder Bed Fusion encompasses several advanced techniques, including Selective Laser Sintering and Electron Beam Melting. This process uses powder material, typically metal or polymer, and fuses it layer by layer using a heat source. High strength and precision characterize parts produced with Powder Bed Fusion. Industries utilize this technology to create complex geometries and lightweight structures, especially in aerospace and medical fields. It significantly reduces material waste, making it a sustainable choice for manufacturing. The ability to design and produce parts with fine details sets Powder Bed Fusion apart, driving innovation across sectors.

Advantages of Large-Scale 3D Printing

Large-scale 3D printing offers significant advantages across various industries. Cost reduction represents one of its most compelling benefits. Companies experience up to 30% less material usage compared to traditional manufacturing methods, leading to savings. Reducing material usage not only cuts costs but also minimizes waste, promoting eco-friendly practices.

Time efficiency plays a vital role in the technology’s appeal. Construction projects benefit from reduced build times, with reports showing decreases of up to 70%. Faster production enables quicker project completion and occupancy, enhancing project turnover rates.

Sustainability emerges as a key factor in large-scale 3D printing. This technology encourages the use of eco-friendly materials and practices, boosting energy efficiency. Traditional construction often produces significant waste, while large-scale 3D printing optimizes resource utilization.

Design flexibility is another notable advantage. Engineers and designers collaborate more effectively, exploring intricate geometries that traditional methods may restrict. Rapid design iterations allow for performance optimization and customization, driving innovation within projects.

Strength and precision come into play with advanced manufacturing technologies. Techniques like Fused Deposition Modeling and Powder Bed Fusion produce high-strength, complex parts. Industries such as aerospace and automotive particularly benefit from this precision, as it enhances performance and safety.

Integration of modular construction techniques stands out as a transformative trend. This approach enables effective scaling of projects, facilitating easier assembly and disassembly. Projects can adapt to changing requirements, enhancing overall efficiency and usability.

Finally, large-scale 3D printing fosters collaboration among various stakeholders. Engineers, designers, and architects can work together seamlessly, sharing insights that generate innovative solutions. Collective expertise results in groundbreaking applications that push industry boundaries.

Challenges and Limitations

Large-scale 3D printing faces numerous challenges that impact its widespread implementation. One significant limitation involves material constraints; not all materials lend themselves to large-scale 3D printing. For example, certain metal alloys and composite materials may require specific printing conditions, placing restrictions on design options.

Cost remains another critical factor. While this technology lowers production costs in many instances, initial investments can be substantial. Equipment, materials, and maintenance contribute to high upfront expenses that might deter smaller companies.

Production speed presents another challenge. Although large-scale 3D printing significantly reduces construction time, projects demanding massive parts may encounter delays. The layer-by-layer approach can affect overall production timelines, especially for intricate designs.

Regulatory hurdles also affect market adoption. Various industries operate under strict regulations that may limit the use of 3D printed components. Compliance with safety and quality standards can complicate integration into established processes.

Quality assurance poses a challenge as well. Variability in machine performance and material properties can lead to inconsistencies in final products. Implementing robust quality control measures is essential but adds complexity to production workflows.

Environmental considerations further complicate the landscape. While many large-scale 3D printing processes aim for sustainability, the overall environmental impact is not yet fully understood. Energy consumption and waste generation during printing processes warrant closer examination.

Despite these challenges, ongoing advancements continue to enhance the technology. Innovative materials and techniques emerge regularly, addressing limitations and expanding application possibilities. Enhanced collaboration among engineers, designers, and regulators fosters progress, driving the next generation of large-scale 3D printing solutions.

Conclusion

Large-scale 3D printing is poised to redefine the landscape of manufacturing and construction. Its ability to create complex structures quickly and sustainably offers a glimpse into a future where efficiency and creativity thrive together. As industries continue to embrace this innovative technology, the potential for cost savings and reduced waste becomes increasingly apparent.

While challenges remain in material selection and regulatory compliance, ongoing advancements promise to overcome these hurdles. The collaborative efforts of engineers and designers will further enhance the capabilities of large-scale 3D printing. As this technology evolves, it will undoubtedly unlock new possibilities across various sectors, paving the way for a more sustainable and efficient future.