Table of Contents

ToggleIn a world where “faster, better, cheaper” isn’t just a catchy slogan but a manufacturing mantra, advanced manufacturing processes are the unsung heroes of industry. These cutting-edge techniques don’t just make products; they transform the way businesses operate, allowing them to produce everything from tiny microchips to massive aircraft components with precision and efficiency. Imagine a factory where robots dance in perfect harmony, producing goods at lightning speed while humans sip coffee and brainstorm the next big innovation.

But it’s not all robots and rainbows. The shift to advanced manufacturing also comes with its own set of challenges, from the need for skilled workers to navigating the complexities of new technologies. Buckle up as we dive into the fascinating world of advanced manufacturing processes, where innovation meets practicality, and the future of production is being shaped today.

Overview of Advanced Manufacturing Processes

Advanced manufacturing processes encompass innovative techniques that significantly improve production capabilities. Technologies such as additive manufacturing enable the creation of complex structures layer by layer. Robotics plays a crucial role in automating repetitive tasks, enhancing speed and precision in operations.

Data analytics and the Industrial Internet of Things (IIoT) contribute to smarter production systems. Real-time data from machines optimizes workflows, resulting in increased efficiency and reduced downtime. Integration of artificial intelligence allows for predictive maintenance, helping to foresee equipment failures before they occur.

Materials science advancements, particularly in smart materials, drive the development of products with enhanced performance characteristics. Manufacturing processes increasingly incorporate nanotechnology, enabling the production of materials with unique properties at the nanoscale. These innovations lead to lightweight, durable components essential in sectors like aerospace and automotive.

Collaborative manufacturing environments foster teamwork between robots and human workers. This synergy promotes better use of resources, combining the strengths of both. Companies that adopt flexible manufacturing systems can quickly respond to changing consumer demands.

Challenges still arise in advanced manufacturing processes. The skills gap presents obstacles to implementing new technologies. A workforce trained in digital skills and advanced techniques remains essential for the successful adoption of these processes. Stakeholders in the manufacturing sector continually seek solutions to address these issues and realize the full potential of advanced manufacturing.

Key Technologies in Advanced Manufacturing

Advanced manufacturing relies on various technologies that drive innovation and efficiency. Four key processes stand out in modern production.

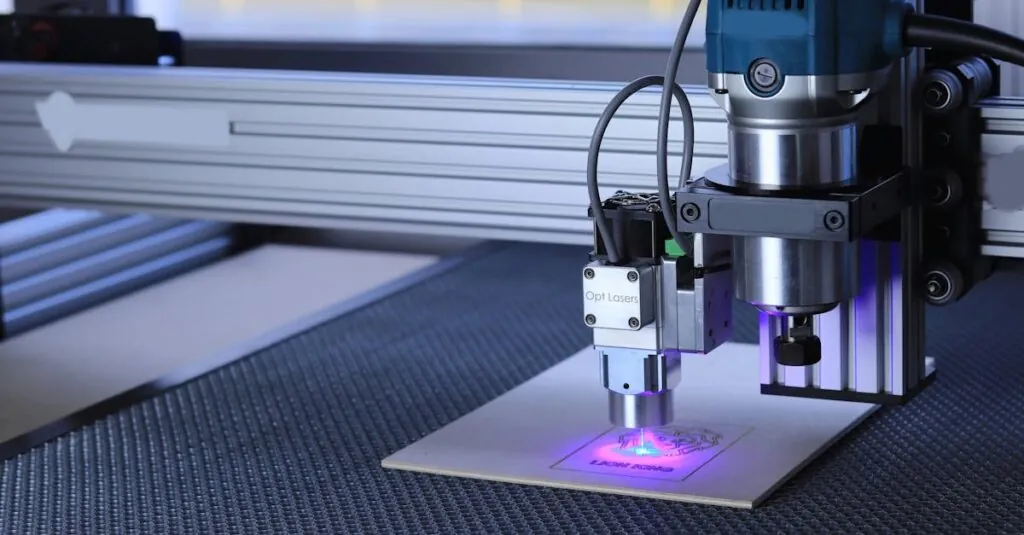

Additive Manufacturing

Additive manufacturing builds objects layer by layer. This process allows for complex geometries that traditional methods can’t achieve. A common example is 3D printing, which uses materials like plastics and metals. The ability to create lightweight yet strong prototypes accelerates product development cycles. Industries ranging from aerospace to healthcare leverage additive manufacturing for customized solutions. This method reduces waste, enhancing sustainability in production.

Subtractive Manufacturing

Subtractive manufacturing involves removing material from a solid block. Techniques like milling, turning, and drilling refine shapes and sizes according to specifications. Companies benefit from precision machining that ensures high-quality finishes. Materials such as metals, plastics, and composites serve as inputs. Subtractive processes support mass production by maintaining repeatability. The efficiency gained from this approach makes it a staple in traditional manufacturing environments.

Hybrid Manufacturing

Hybrid manufacturing combines additive and subtractive techniques. This approach enables manufacturers to tackle more complex tasks in a single setup, reducing lead times. The integration allows for builds that start with additive processes, followed by precise subtractive finishing. Adoption of hybrid systems enhances part functionality and diversity. Industries favor this method for its versatility, making it ideal for both prototypes and final products. The fusion of technologies represents the future of production efficiency.

Benefits of Advanced Manufacturing Processes

Advanced manufacturing processes offer significant advantages across various industries. These benefits include increased efficiency, enhanced product quality, and sustainability considerations.

Increased Efficiency

Advanced manufacturing processes streamline operations. Automation reduces time spent on repetitive tasks, allowing faster production cycles. Data analytics optimize workflows by identifying bottlenecks, leading to more effective resource allocation. As a result, companies achieve higher throughput and minimize downtime. Robotics add precision and speed, handling complex tasks that would require more time for human workers. Ultimately, increased efficiency translates to reduced costs, benefiting both manufacturers and consumers.

Enhanced Product Quality

Enhanced product quality stems from advanced manufacturing methods. Techniques like additive manufacturing enable the creation of intricate designs with precise dimensions. Materials with superior properties contribute to better performance and durability. Rigorous data analysis ensures consistent quality control, identifying defects early in the process. With improved monitoring systems, manufacturers can respond quickly to quality issues, maintaining high standards throughout production. Consequently, consumers receive reliable products that meet or exceed expectations.

Sustainability Considerations

Sustainability considerations play a crucial role in advanced manufacturing. Innovative processes minimize waste, utilizing resources more effectively. Additive manufacturing, for instance, typically generates less scrap compared to traditional methods. Energy-efficient technologies reduce the carbon footprint, aligning with global sustainability goals. The use of eco-friendly materials also supports greener practices, appealing to environmentally conscious consumers. By adopting these advanced techniques, manufacturers contribute to a more sustainable future while remaining competitive in the market.

Challenges in Implementing Advanced Manufacturing

Advanced manufacturing processes introduce several challenges that companies face as they adopt these innovative methods. Addressing these challenges is essential for successful implementation.

High Initial Costs

High initial costs present a significant barrier to adopting advanced manufacturing technologies. Investments in equipment, technology, and infrastructure often require substantial capital. For instance, a comprehensive additive manufacturing machine can cost over $1 million. Companies also incur expenses related to training staff and integrating new systems into existing workflows. Budget constraints may inhibit smaller manufacturers from pursuing such investments. Despite these challenges, potential long-term savings can offset these upfront costs. Achieving efficiency and improved production capabilities can justify the initial investment over time.

Skills Gap in Workforce

The skills gap in the workforce complicates the implementation of advanced manufacturing. Many workers lack the necessary expertise in digital tools and techniques. Training programs are essential for bridging this gap, yet they require time and resources. Businesses often struggle to find candidates with experience in areas like robotics and data analytics. A skilled workforce is crucial for leveraging new technologies effectively. Collaborative efforts between educational institutions and industries can facilitate better training opportunities, ensuring that employees possess the skills needed for advanced manufacturing processes.

Supply Chain Complexity

Supply chain complexity poses another challenge for advanced manufacturing. Modern production methods often necessitate intricate supply networks, which can lead to bottlenecks. Variability in material availability affects scheduling and can disrupt production timelines. Global supply chains further complicate logistics, exposing manufacturers to risks associated with geopolitical or environmental factors. Managing these complexities requires enhanced communication and coordination among suppliers. Implementing data analytics tools can provide real-time insights, aiding companies in navigating supply chain obstacles effectively. Enhanced supply chain management contributes to smoother operations in the context of advanced manufacturing.

Future Trends in Advanced Manufacturing Processes

The future of advanced manufacturing processes hinges on innovation and technology. As industries evolve, automation and artificial intelligence become essential.

Automation and AI Integration

Automation plays a crucial role in enhancing manufacturing efficiency. AI systems analyze vast amounts of data, optimizing production schedules and reducing downtime. Robotics streamline repetitive tasks, allowing human workers to focus on complex challenges. Manufacturers adopt machine learning algorithms to predict equipment failures before they occur, ensuring seamless operations. Enhanced safety measures using AI technologies also contribute to safer work environments. The integration of these advanced technologies fosters a responsive manufacturing ecosystem where operational flexibility thrives.

Customization and Personalization

Customization and personalization shape the landscape of advanced manufacturing. Technologies like 3D printing allow for tailored solutions that meet specific customer needs. Manufacturers increasingly focus on unique designs, enhancing product appeal and satisfaction. Data analytics enables companies to understand consumer preferences, driving the creation of bespoke products. Shorter production runs become more feasible, allowing rapid adjustments to market demands. This capability transforms traditional mass production approaches, positioning manufacturers to compete in niche markets effectively.

Advanced manufacturing processes are reshaping the industrial landscape by combining innovation with efficiency. As technology continues to evolve, manufacturers are better equipped to meet the demands of a dynamic market. The integration of automation and artificial intelligence not only enhances productivity but also allows for greater customization and sustainability.

While challenges remain in workforce training and initial investment costs, the long-term benefits of adopting these advanced techniques are undeniable. The future promises even more exciting developments as companies leverage data analytics and collaborative environments to drive innovation. Embracing these changes will be crucial for manufacturers aiming to thrive in an increasingly competitive marketplace.